1, Recently, domestic label printing mainly uses letterpress printing, offset printing, flexographic printing and screen printing. From a technical point of view, these printing methods have their own advantages and disadvantages. There is no other printing method that can replace others.

(1) Offset printing

Offset printing is a relatively widespread printing method. Domestic sheet-fed printing is basically the world of offset printing. This printing method is fast, high-definition printing, accurate overprinting, and full printing layers, but it has poor durability and relatively high ink layer. Light, not suitable for printing brightly colored label products.

(2) Letterpress printing

Letterpress printing reproduces graphics and texts with good clarity, higher printing speed, stronger color strength and durability than offset printing, and slightly worse than screen printing, but the level of expression and registration are stronger than screen printing and flexo printing, so domestic Most of the labels are produced by letterpress printing.

(3) screen printing

The biggest advantage of screen printing is that the ink layer is thick, the hiding power is good, but the speed is slow, the gradation is poor, and the registration is low (this refers to the general domestic level), so the screen printing machine can be used to print with a weak sense of layering. s Mark.

(4) flexographic printing

The print characteristics of flexographic printing are relatively in the middle. This method is used to print labels in foreign countries. However, this technology requires a high level of anilox roller processing and the technical level of the workers. Although the machine is relatively simple, the process is quite complicated. Not many labels are printed in this way in China.

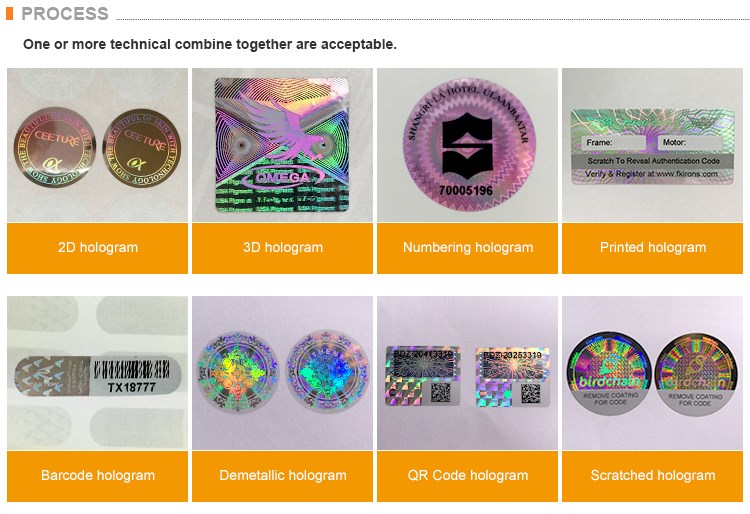

2, To print the most exquisite labels, it is necessary to effectively combine various processes in the printing process, integrate the advantages of various printing methods, and form a greater combination of advantages.

The purpose of multi-process combination

(1) Effective anti-counterfeiting effect:

Use multiple process effects to print on the same label product, especially on the labels of some cosmetics and food packaging that are easy to be faked. This printing method allows consumers to see the product at a glance through the label. The true and false, thereby protecting the interests of product manufacturers and consumers, but also won an excellent reputation for the printing factory.

(2) Improve the quality of printed products:

the combination of multiple processes combines the advantages of various printing processes, so this combined printing method can guarantee the printing effect of the printed products to the greatest extent, so as to meet the increasing sensory requirements of people, and at the same time improve the printing factory The quality of printing, which brings more livelihoods for it. Improve production efficiency and reduce costs. The combination of multiple processes also includes the combination of printing and post-pressing processes. In product production, printing and post-pressing are completed at one time, and the finished product is directly produced, which can greatly reduce costs.

3, The machine with multi-process combination has the following two forms

(1) One is a single-machine combination:

in the trademark printing machine, we are more common in the diagonal machine, which can complete the functions of printing, bronzing, die-cutting, and waste discharge on one machine, but because it is a single-machine printing, the printing size Will be affected.

(2) The other is the combination of units into a production line:

it combines embossing, screen printing, flexo printing, hot stamping, die-cutting and other printing and post-press processing process units to form an assembly line for printing production, and realizes a combination of multiple processes on the same product Effect. This combined printing production method meets the needs of the development of the label market. The grade of printed products has been greatly improved. At the same time, it has brought huge profits for printing manufacturers. The development of unit-type production lines in China has become more and more popular. Optimistic. The combination of letterpress, flexographic and screen printing in label printing.